Type MC-IAC Interlocked Armor Power Cables Non Shielded 2.4kV

APPLICATIONS:

Where NEC jurisdiction applies; as Type MV-105 cable for installation aerially in conduits or in underground ducts, direct buried, or isolated in air, dry or wet locations, in cable trays, or with messenger, for power and control circuits not exceeding 2400 volts in manufacturing and processing plants, substations and generating stations. When installed per NEC, cables meet the requirements of OSHA. Otherwise, for general-purpose applications where the protection of interlocked armor is required.

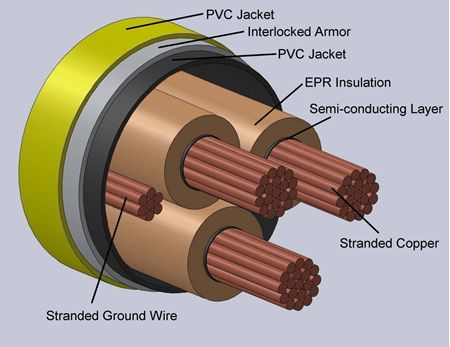

CONSTRUCTION:

Three conductors of stranded copper, extruded semi-conducting layer, 115-mil EPR (Ethylene Propylene Rubber) insulation, phase identification. Three conductors twisted together with a stranded copper grounding conductor in one interstice, suitable fillers, binder tape, aluminum interlocked armor, yellow PVC (Polyvinyl Chloride) jacket overall, surface printed.

STANDARDS:

- Conforms to MV-105 and MC specs per UL 1072.

- Overall jacket suitable for Sunlight Resistant and Direct Burial applications.

- Cables designed to pass the IEEE-383 ribbon burner flame test and are suitable “For CT Use.”

- Cables meet the requirements of ICEA S-96-659.

|

BASIC CAT. NO. |

SIZE/AWG |

NO. OF STRDS. |

O.D OVER |

JKT. THICK. |

O.D OVER |

COPPER |

WEIGHT |

PHASE |

|---|---|---|---|---|---|---|---|---|

|

9-3006-G |

4 |

7 |

1.33 |

50 |

1.43 |

6 |

1115 |

105 |

|

9-3007-G |

2 |

7 |

1.44 |

50 |

1.54 |

6 |

1430 |

140 |

|

9-3008-G |

1 |

19 |

1.51 |

50 |

1.61 |

4 |

1770 |

160 |

|

9-3009-G |

1/0 |

19 |

1.60 |

60 |

1.72 |

4 |

2025 |

185 |

|

9-3010-G |

2/0 |

19 |

1.72 |

60 |

1.85 |

4 |

2390 |

215 |

|

9-3011-G |

3/0 |

19 |

1.83 |

60 |

1.96 |

3 |

3000 |

250 |

|

9-3012-G |

4/0 |

19 |

1.95 |

60 |

2.08 |

3 |

3395 |

285 |

|

9-3013-G |

250 |

37 |

2.07 |

60 |

2.20 |

3 |

3900 |

320 |

|

9-3015-G |

350 |

37 |

2.30 |

75 |

2.46 |

2 |

5105 |

395 |

|

9-3017-G |

500 |

37 |

2.57 |

75 |

2.73 |

1 |

6800 |

485 |

|

9-3019-G |

750 |

61 |

2.98 |

75 |

3.14 |

1/0 |

9400 |

615 |

|

9-3020-G |

1000 |

61 |

3.28 |

75 |

3.43 |

1/0 |

12050 |

770 |