TYPE VFD/TECK-90 Interlocked Armor Power Cables

| DOWNLOADS | |

| TYPE VFD/TECK-90 SPEC. SHEET | |

APPLICATIONS:

Teck-90 cable is suitable for use in exposed or concealed wiring at temperatures of 90°C in dry or wet locations, in ventilated or ladder type cable trays in dry or wet conditions, on walls or beams, or directly buried, for power and control circuits not exceeding 600 volts in manufacturing and processing plants, substations and generating stations. Suitable for use in NEC Hazardous locations: Class I, Div. 2 and Class II, Div. 2. Suitable for variable frequency drive applications.

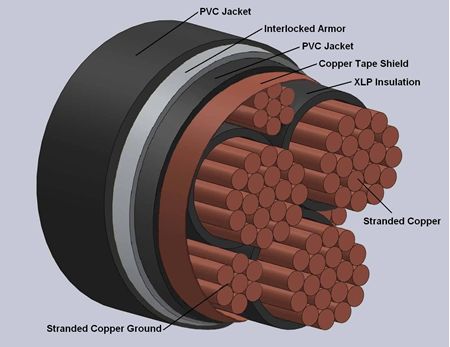

CONSTRUCTION:

Stranded copper conductors, XLP (Cross-Linked Polyethylene) insulated, Method 4 phase-identified; three insulated conductors cabled together with one stranded copper grounding conductor in each of the interstices and each in contact with helically applied copper tape shield, inner black PVC (Polyvinyl Chloride) jacket, aluminum interlocked armor, black PVC jacket overall, surface printed.

STANDARDS:

- Copper conductors conform to ASTM B-3 & B-8.

- Individual conductors conform to UL Standard 44, and are approved as Type XHHW-2.

- MC Type cable per UL 1569, and TECK-90 Type per CSA Std. C22.2.

- Cables suitable for sunlight resistant and direct burial applications.

- Cables designed to pass the IEEE-383 and IEEE-1202 tests.

- Cables meet requirements of ICEA S-95-658/NEMA WC70.

|

BASIC CAT. NO. |

SIZE/AWG |

STRAND |

INSUL. THICK. |

GRD WIRES. |

DIAMETER OVER |

WEIGHT | ||

|---|---|---|---|---|---|---|---|---|

|

INNER JKT in. |

ARMOR in. |

OVERALL in. | ||||||

|

9-103-GS |

14 |

7 |

30 |

3#18 |

.41 |

.63 |

.73 |

310 |

|

9-203-GS |

12 |

7 |

30 |

3#16 |

.45 |

.67 |

.77 |

365 |

|

9-303-GS |

10 |

7 |

30 |

3#14 |

.49 |

.71 |

.81 |

450 |

|

9-651-GS |

8 |

7 |

45 |

3#14 |

.65 |

.85 |

.95 |

550 |

|

9-652-GS |

6 |

7 |

45 |

3#12 |

.74 |

.95 |

1.05 |

700 |

|

9-653-GS |

4 |

7 |

45 |

3#10 |

.86 |

1.06 |

1.16 |

930 |

|

9-654-GS |

2 |

7 |

45 |

3#8 |

.99 |

1.28 |

1.38 |

1350 |

|

9-655-GS |

1 |

19 |

55 |

3#6 |

1.12 |

1.52 |

1.62 |

1750 |

|

9-656-GS |

1/0 |

19 |

55 |

3#6 |

1.21 |

1.56 |

1.66 |

2030 |

|

9-657-GS |

2/0 |

19 |

55 |

3#6 |

1.29 |

1.65 |

1.77 |

2400 |

|

9-658-GS |

3/0 |

19 |

55 |

3#4 |

1.42 |

1.82 |

1.94 |

2970 |

|

9-659-GS |

4/0 |

19 |

55 |

3#4 |

1.53 |

1.90 |

2.02 |

3480 |

|

9-660-GS |

250 |

37 |

65 |

3#4 |

1.74 |

2.20 |

2.32 |

4080 |

|

9-661-GS |

300 |

37 |

65 |

3#3 |

1.85 |

2.21 |

2.33 |

4675 |

|

9-662-GS |

350 |

37 |

65 |

3#2 |

1.96 |

2.34 |

2.46 |

5380 |

|

9-663-GS |

500 |

37 |

65 |

3#1 |

2.24 |

2.64 |

2.79 |

7345 |

|

9-665-GS |

750 |

61 |

80 |

3#2/0 |

2.70 |

3.08 |

3.23 |

10820 |

|

9-666-GS |

1000 |

61 |

80 |

3#3/0 |

3.08 |

3.58 |

3.75 |

13800 |